PLASTIC ADDITIVES

We control the properties of diverse plastic materials to enrich everyday life.

Plastic materials are vulnerable to deterioration and discoloration due to heat, light, and oxygen exposure.

Plastic additives can control and suppress defects in the production process caused by various deterioration.

In recent years, there is a growing awareness of environmental needs, and environmentally-friendly products are receiving greater attention.

One example is a worldwide demand to reduce toxic heavy metals which impact the environment.

Our company is proud to offer a wide range of alternative products with low environmental impact and excellent processibility, such as calcium/zinc-based composite stabilizers.

PRODUCT LIST

Metallic Soap

■Overview

Metallic soaps are powder compounds derived from fatty acids and metal salts with surfactant properties.

They are known to have a melting point higher than common wax.

Sakai Chemical Industry offers a lineup of both dry and wet products to allow for development to match diverse product applications.

Characteristics of Metallic Soap

Lubricant / Mold Release / Glidant

Reduces friction and adhesion between plastics and the metal surface of processing machinery and improves

lubrication and release from molds. Some metallic soaps are widely used as a lubricant layer for plastics and

casting molds.

Dispersivity / Lubricativity /

Prevents Blockage

Although it is a powder mixture, it provides a strong aggregation relaxation effect which is used to improve the dispersivity of pigments and other powders. In addition, metallic soaps of magnesium and calcium are also used in the pharmaceutical and cosmetic segments due to their high safety rating.

Gelling / Viscosity Enhancing /

Thickening

Metallic soaps provide gel formation in organic solvents (three-dimensional mesh structure) and form

rheological properties. For these reasons, they are used to adjust viscosity and prevent dripping in paints and

as thickeners for soap-based grease.

Thermal Stabilizer /

Vulcanization Accelerator

Widely used as polyvinyl chloride heat stabilizers, polyolefin plastic neutralizers, and rubber vulcanization

accelerators due to the reactivity of polarized parts (metal parts).

Water Repellent / Moisture-Proof

Also used for water repellent and moisture-proof applications due to strong water repellent properties of

fatty acids. Although it is a powder mixture, it provides a strong water repellent effect which is used to

prevent moisture absorption in powders.

■Production Methods

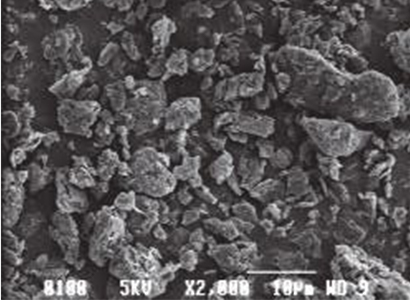

Metallic soaps have a variety of characteristics due to different production methods in addition to significant changes in particle size and shape.

Dry Method

They react with metal oxides and hydroxides directly without generating by-products. Particle size is controlled by crushing to offer a lineup of sizes from

granules to fine powders.

2RCOOH+MO → (RCOO)2M+H2O

2RCOOH+M(OH)2 → (RCOO)2M+2H2O

SM-P

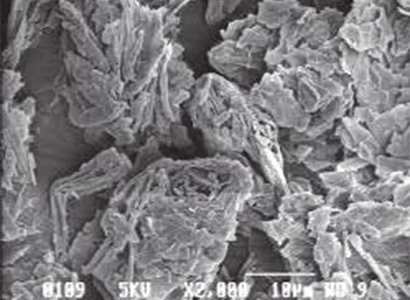

Wet Method

Make sodium salts of fatty acids react with metal salts in an aqueous solution. Scale-like fine powders form due to precipitation reaction. The wet method

characteristically produces a higher volume of particles with a sharper size distribution than the dry method. Sakai Chemical Industry leverages its

proprietary technologies to offer a lineup of fine particle products.

2RCOOH+NaOH→2RCOONa+2H2O

2RCOONa+MCI2 → (RCOO)2M+2NaCI

■Applications

Neutralizers, water repellents, dispersants, thickeners, mold release agents, and a wide range of other uses

Examples: Raw materials for PVC stabilizers (Ca/Zn-based, Ba/Zn-based), neutralizers for PO plastics, water repellent for cement, solvent dispersion grease

enhancers.

■Features

We can provide both dry method products for general-purpose use and wet method products with sharp particle sizes.

In addition, we have unique technology for surface treatments and control of particle sizes to satisfy the diverse needs of our clients.

Wide Product Lineup and Proven Achievement Record

Our product lineup includes industrial grades, Ca-St for health food products, and Mg-St for pharmaceutical use.

We are fully prepared with various fatty acids and metal salts and a wide lineup thanks to multiple production methods (dry and wet methods).

※Sakai Chemical Industry also sells metallic soaps with added value, including ultrafine particles and grades for food additives and Japanese pharmacopeia.

Industrial Grade

| Fatty acid | Metal salt | Shape | Product Name | Features and Applications | Package | Weight (kg) | Materials |

|---|---|---|---|---|---|---|---|

| Stearic acid | Zn | Powder | SZ-2000 | Wet method, standard grade. | B/G | 10 | |

| Powder | SZ-P | Dry method, standard grade. | B/G | 10 | |||

| Powder | SZ-PG | Special purpose product. Granule version of SZ-P. |

B/G | 10 | |||

| Powder | SZ-T | Dry method, transparent grade. | B/G | 10 | |||

| Powder | SZ-TF | Dry method, fine powder grade. | B/G | 10 | |||

| Powder | SZ-TG | Dry method, granule grade. | B/G | 10 | |||

| Powder | SPZ-100F | Wet method, ultrafine particles. Special grade. |

B/G | 10 | |||

| Ca | Powder | SC-100 | Wet method, standard grade. | B/G | 10 | ||

| Powder | SC-P | Dry method, standard grade. | B/G | 10 | |||

| Powder | SC-PG | Special purpose product. Granule version of SC-P. |

B/G | 10 | |||

| Mg | Powder | SM-1000 | Wet method, standard grade. | B/G | 10 | ||

| Powder | SM-P | Dry method, standard grade. | B/G | 10 | |||

| Powder | SM-PG | Special purpose product. Granule version of SC-P. |

B/G | 10 | |||

| Powder | SPX-100F | Wet method, ultrafine particles. Special grade. |

B/G | 10 | |||

| Al | Powder | SA-1000 | Wet method, standard grade. | B/G | 10 | ||

| Powder | SA-1500 | Wet method, intermediate grade of SA-1000 and SA-2000. | B/G | 10 | |||

| Powder | SA-2000 | Wet method, high water repellence grade. | B/G | 10 | |||

| Ba | Powder | SB | Wet method, standard grade. | B/G | 10 | ||

| Li | Powder | S-7000 | Wet method, standard grade. | B/G | 10 | ||

| 12-Hydroxystearic acid | Li | Powder | S-7000H | Wet method, standard grade. | B/G | 10 | |

| Special Purpose Products | Powder | LBT-1830 | Zinc stearyl acid phosphate. Provides glidant property and mold release in a wide range of temperatures. | B/G | 10 | ||

| Powder | LBT-1830精製 | Zinc stearyl acid phosphate. Provides glidant property and mold release in a wide range of temperatures. Version with low impurities. | B/G | 10 | |||

Food Additive and Pharmaceutical Use Grade

Inquiries

PLASTIC ADDITIVE SALE DEPARTMENT SALES &

MARKETING DIVISION

TEL (Tokyo) +81-3-5823-3723

(Osaka) +81-72-223-4155

Hydrotalcite

■Summary

It is a powder compound with a layer of Mg and Al, has a layered structure with water and carbonate ions between them, and has the property of taking in

anions.

■Features

・In addition to offering hydrotalcite as a simple substance, we also offer an advanced improved approach mixed with our formulation technology of

stabilizers.

・We have production sites in Japan and overseas SCVN (Vietnam )

| Product Name | Composition | Shape | Features and Applications | Package | Weight (kg) | Materials |

|---|---|---|---|---|---|---|

| HT-1 | Mg4Al2(OH)12CO3・3H2O | Powder | General-purpose type. | B/G | 20 | - |

| HT-P | Mg4.5Al2(OH)13CO3・3.5H2O | Powder | Olefin grade. Good acid-binding function. | B/G | 20 | |

| HT-7 | Mg3.5Zn0.5Al2(OH)12CO3・3H2O | Powder | High transparency, low coloration. | B/G | 20 | |

| HT-6 | Mg6Al2(OH)16CO3・4H20 | Powder | Non-coat, high BET type. | B/G | 20 | |

| HT-9 | Mg(1-x)Alx(OH)2(CO3)x/2・mH2O | Powder | Completely burnt type. Grade for high-temperature processing resistance. |

B/G | 15 | |

| HT-1-NC | Same as HT-1 | Powder | Non-coat version of HT-1. | B/G | 20 |

Inquiries

PLASTIC ADDITIVE SALE DEPARTMENT SALES &

MARKETING DIVISION

TEL (Tokyo) +81-3-5823-3723

(Osaka) +81-72-223-4155

Flame Retardants

1. Melamine Cyanurate

Melamine cyanurate (MC) is a compound derived from melamine and cyanuric acid.

■Features

・Multilayer structure compound with high nitrogen content.

・Environmentally friendly, non-halogen flame retardant.

・Excellent synergetic effect when used together with phosphorus flame retardants and hydrated metal compounds.

| Product Name | Shape | Features and Applications | Package | Weight (kg) | Materials |

|---|---|---|---|---|---|

| MC-2010N | Powder | General-purpose grade. | B/G | 20 | - |

| MC-20S | Powder | Version of MC-2010N with surface treatment. | B/G | 20 |

2. Composite Magnesium Hydroxide MGZ Series

| Product Name | Shape | Features and Applications | Package | Weight (kg) | Materials |

|---|---|---|---|---|---|

| MGZ-5R | Powder | Grade with excellent acid resistance. Reduces dielectric dissipation factor. | B/G | 20 | - |

| MGZ-6R | Powder | Version of MGZ-6R with fine particles. | B/G | 20 |

Inquiries

PLASTIC ADDITIVE SALE DEPARTMENT SALES &

MARKETING DIVISION

TEL (Tokyo) +81-3-5823-3723

(Osaka) +81-72-223-4155